The slipper industry is evolving, and technology is at the forefront of this transformation. From smart materials to AI-driven designs, advanced technologies are reshaping how slippers are made. What advantages do these innovations offer?

Advanced technologies enable slipper brands to improve efficiency, enhance quality, and deliver customized products with sustainability at their core.

In this article, I’ll explore how cutting-edge technologies like automation, AI, and 3D printing are driving change in slipper manufacturing.

How does automation improve efficiency in slipper production?

Automation streamlines processes, reducing labor costs and increasing production speed.

Automated systems in slipper manufacturing ensure consistent quality, faster production cycles, and lower costs.

Dive deeper: Benefits of automation in slipper manufacturing

- Precision and Consistency: Automated cutting and stitching machines produce high-quality results with minimal errors.

- Increased Output: Robotic assembly lines can operate 24/7, ensuring higher production rates.

- Cost Savings: Reducing manual labor needs helps lower operational costs.

Example:

- Tiancheng Garments IM&EX CORP., LTD. utilizes automated cutting tools to deliver precision-crafted slippers efficiently, ensuring scalability and quality.

| Automation Process | Key Benefit | Example Implementation |

|---|---|---|

| Robotic Stitching | Uniform product quality | Auto-sewing slipper uppers |

| Automated Material Cutting | Reduced waste | Laser-cut eco-friendly soles |

| Conveyor Assembly Lines | Faster production cycles | Mass production for wholesale |

How do AI and data analytics enhance slipper design?

AI transforms slipper design by predicting trends and optimizing customer experiences.

AI tools analyze consumer preferences and market trends, enabling brands to create stylish, functional, and on-demand designs.

AI-driven insights help predict best-selling styles and optimize production schedules.

Dive deeper: AI-powered design and production advantages

- Trend Prediction: AI can forecast upcoming design preferences using market data.

- Customization: AI tools recommend designs based on customer input, creating personalized slippers.

- Supply Chain Optimization: Data analytics ensure efficient material sourcing and inventory management.

Example of AI in Action:

- Nike’s AI-driven design process predicts customer preferences and adjusts production plans, leading to efficient, data-backed decision-making.

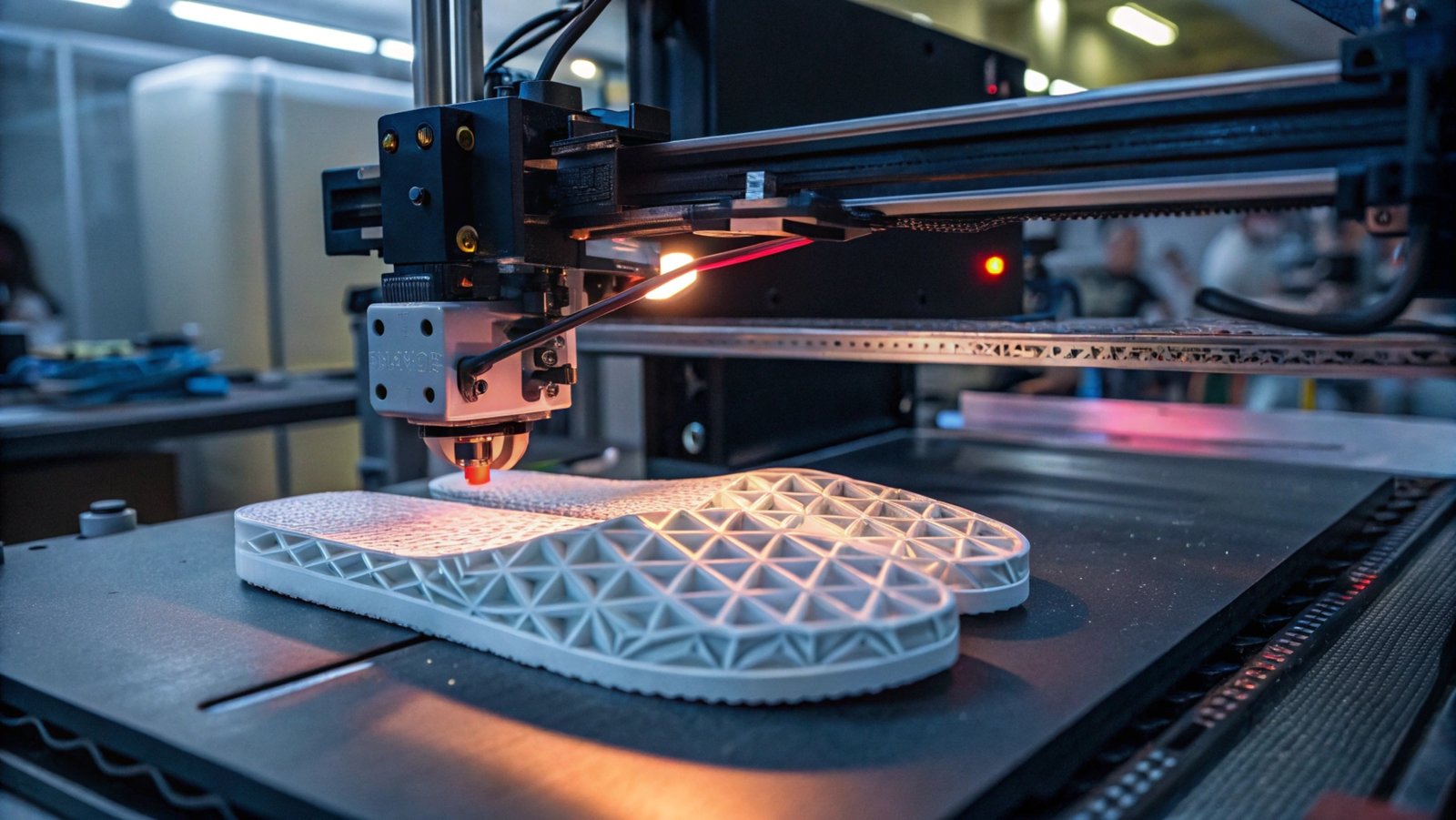

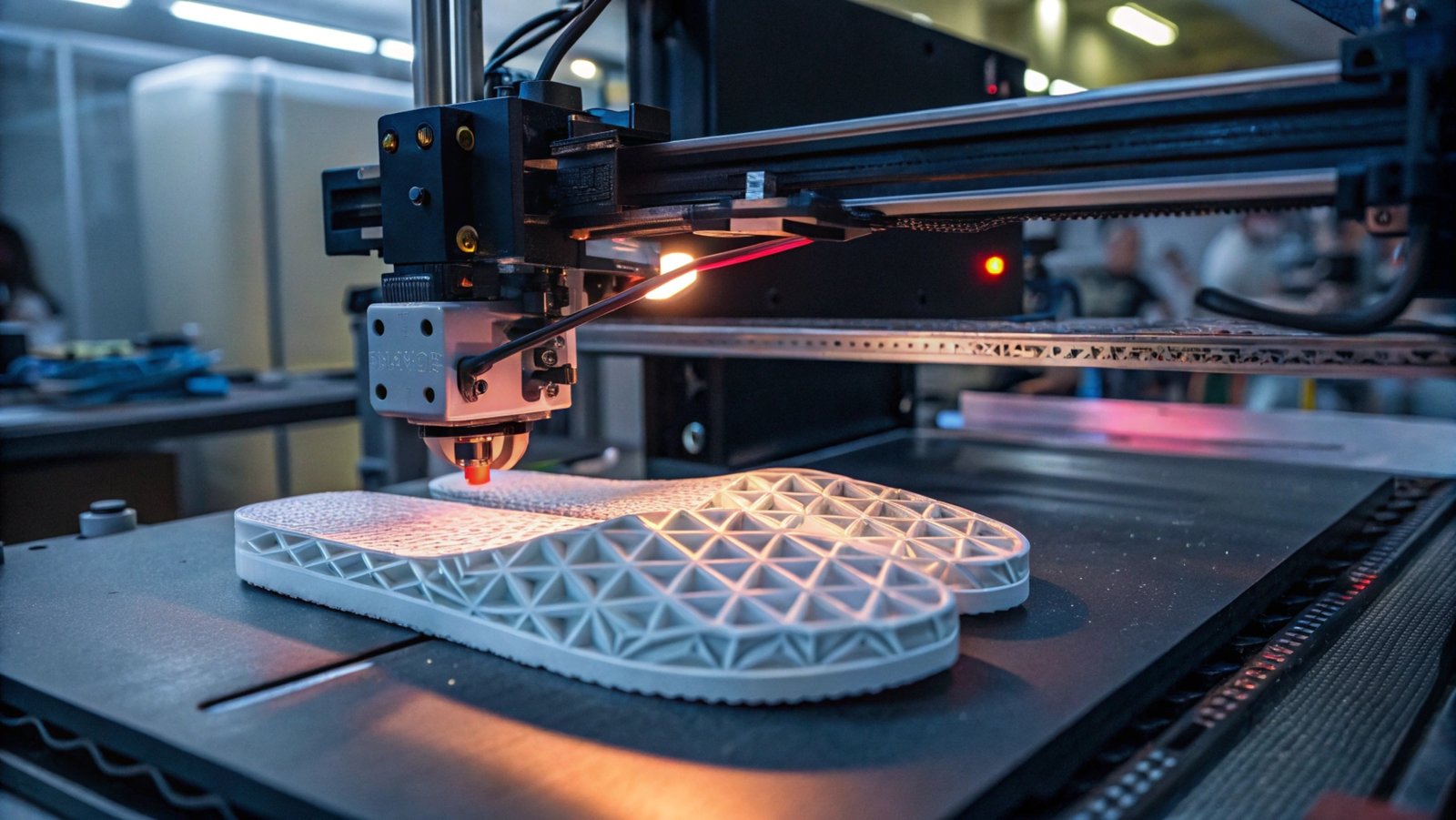

How does 3D printing revolutionize slipper manufacturing?

3D printing is redefining how slippers are made, offering unparalleled flexibility and sustainability.

With 3D printing, manufacturers can produce highly detailed and customizable slipper prototypes quickly and affordably.

Dive deeper: Advantages of 3D printing

- Prototyping Speed: Design ideas can move from concept to prototype within hours.

- Customization: Customers can request personalized features that are quickly implemented.

- Reduced Waste: Additive manufacturing uses only the necessary materials, minimizing waste.

Real-World Example:

- Adidas’ 4D line integrates 3D-printed midsoles for enhanced comfort and design flexibility.

- Allbirds uses 3D printing for sustainable prototypes, supporting their eco-friendly mission.

What role does sustainability-focused technology play?

Sustainability is a critical driver for innovation in the slipper industry.

Advanced technologies enable eco-friendly practices, from using recycled materials to improving energy efficiency in production.

Technological advancements also allow brands to track and report their sustainability metrics, building trust with eco-conscious customers.

Dive deeper: Examples of sustainable technologies

- Recycled Material Integration: Technologies convert plastic waste into usable slipper materials.

- Energy-efficient Processes: Smart systems minimize energy usage during production.

- Blockchain for Transparency: Blockchain tracks the supply chain, verifying eco-friendly practices.

Example Brands:

- Rothy’s integrates tech into their sustainable manufacturing processes.

- TOMS uses blockchain to ensure supply chain transparency.

Conclusion

Advanced technologies like automation, AI, and 3D printing empower slipper manufacturers to deliver high-quality, customized, and sustainable products efficiently. These innovations are reshaping the industry for a tech-driven future.