a large scale modern footwear manufacturing workshop

If you’re planning to produce high-quality slippers, choosing the right manufacturing machine is crucial. But what exactly is the best machine for the job? Let’s find out.

The best slippers manufacturing machine depends on your production needs. EVA injection molding machines and PU pouring machines are popular for large-scale, efficient slipper production.

Let’s explore the different types of machines and what makes them ideal for slipper manufacturing.

[Table of contents]

What Are the Main Types of Slipper Manufacturing Machines?

When it comes to producing slippers, different machines serve different purposes. Your choice will depend on materials, production volume, and budget.

The main machines are EVA injection molding machines, PU pouring machines, and cutting/pressing machines for different slipper components.

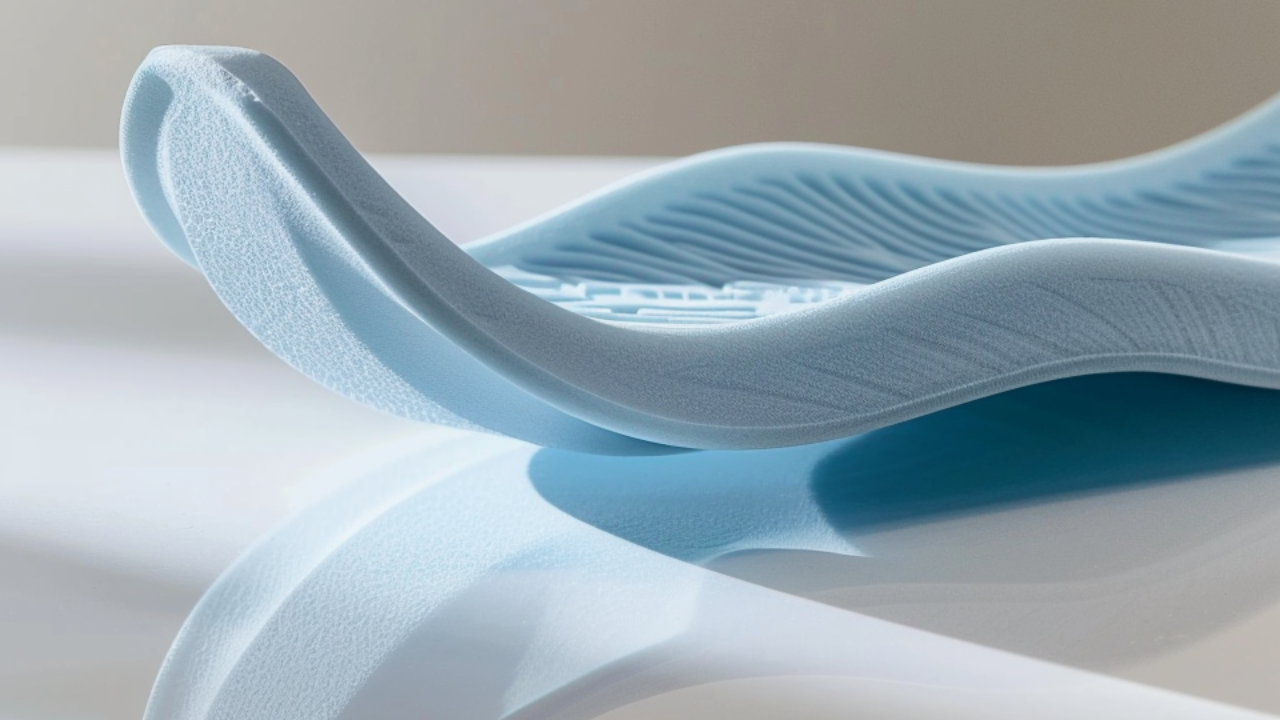

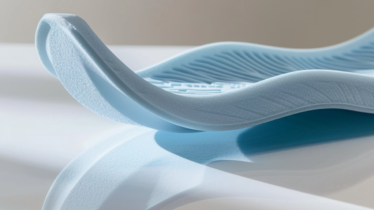

a dual layer sole combining a soft eva top

a dual layer sole combining a soft eva top

Key Types of Slipper Machines

| Machine Type | Purpose | Best for |

|---|---|---|

| EVA Injection Molding Machine | Molding soles and slipper shapes | Large-scale production, durability |

| PU Pouring Machine | Producing soft and lightweight soles | Comfortable slippers |

| Sole Cutting Machine | Cutting soles from sheet materials | Customized designs |

| Upper Stitching Machine | Attaching uppers to soles | Precision stitching and details |

- EVA Injection Molding Machines: Best for bulk production of durable, waterproof soles.

- PU Pouring Machines: Produce soft and flexible soles ideal for home slippers.

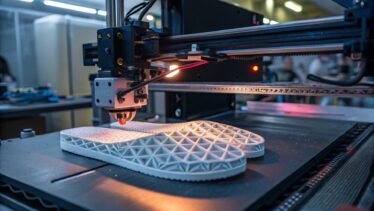

Why Choose EVA Injection Molding Machines for Slippers?

EVA injection molding machines are the most popular choice for slipper manufacturers. They are efficient, fast, and cost-effective.

EVA machines mold durable, waterproof soles quickly, making them ideal for beach slippers, sandals, and garden shoes.

Advantages of EVA Machines

- High Efficiency: Produces large quantities in short time.

- Durability: EVA soles are long-lasting and water-resistant.

- Cost-Effective: Low operating costs and minimal waste.

EVA injection molding machines are widely used in factories producing flip flops and outdoor slippers because of their durability and scalability.

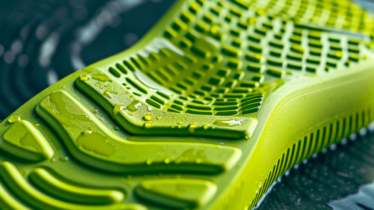

How Do PU Pouring Machines Improve Slipper Comfort?

PU (Polyurethane) pouring machines are ideal for soft, cushioned slipper soles. This is perfect for indoor or home-use slippers.

Key Features of PU Machines

- Comfortable Soles: PU material is soft and flexible.

- Lightweight Design: Suitable for bedroom and home slippers.

- Customization: Machines allow custom designs and colors.

If your target market prioritizes comfort, PU pouring machines are the best choice for producing premium-quality home slippers.

What Machines Are Needed for Customized Slipper Production?

Customized slippers often involve additional steps, such as cutting, stitching, and printing.

For customization, you need sole cutting machines, stitching machines, and printing equipment for personalized designs.

Machines for Customization

| Machine Type | Purpose |

|---|---|

| Sole Cutting Machine | Cuts soles to desired shapes/sizes |

| Upper Stitching Machine | Attaches upper material to soles |

| Heat Transfer Printing Machine | Prints logos, designs, and patterns |

These machines allow manufacturers to meet branding needs and offer unique, customized slipper designs for clients.

What Factors Should You Consider When Choosing a Machine?

Choosing the right slippers manufacturing machine depends on your production goals, budget, and materials.

Consider production volume, slipper material, machine efficiency, and customization features when selecting a machine.

Factors to Evaluate:

- Production Volume: Large-scale production requires high-output machines like EVA molding machines.

- Material Compatibility: EVA or PU machines suit different slipper types.

- Customization Needs: Printing and cutting machines are essential for branded designs.

- Budget: Factor in operating costs, energy efficiency, and long-term maintenance.

Evaluate these aspects to find the best machine that aligns with your manufacturing goals.

Conclusion

The best slippers manufacturing machine depends on your needs. EVA injection machines are perfect for durable, high-volume production, while PU pouring machines excel at soft, comfortable soles.